Industrial Epoxy

Find More Details On

When considering flooring options for your industrial space, industrial epoxy emerges as a practical and long-lasting solution. Its seamless finish and durability make it a popular choice for areas that endure heavy wear and tear. But what sets industrial epoxy apart goes beyond its resilience. The versatility and customization options available might just surprise you. So, before making your final decision, make sure you explore all the possibilities that industrial epoxy can offer for your facility's flooring needs.

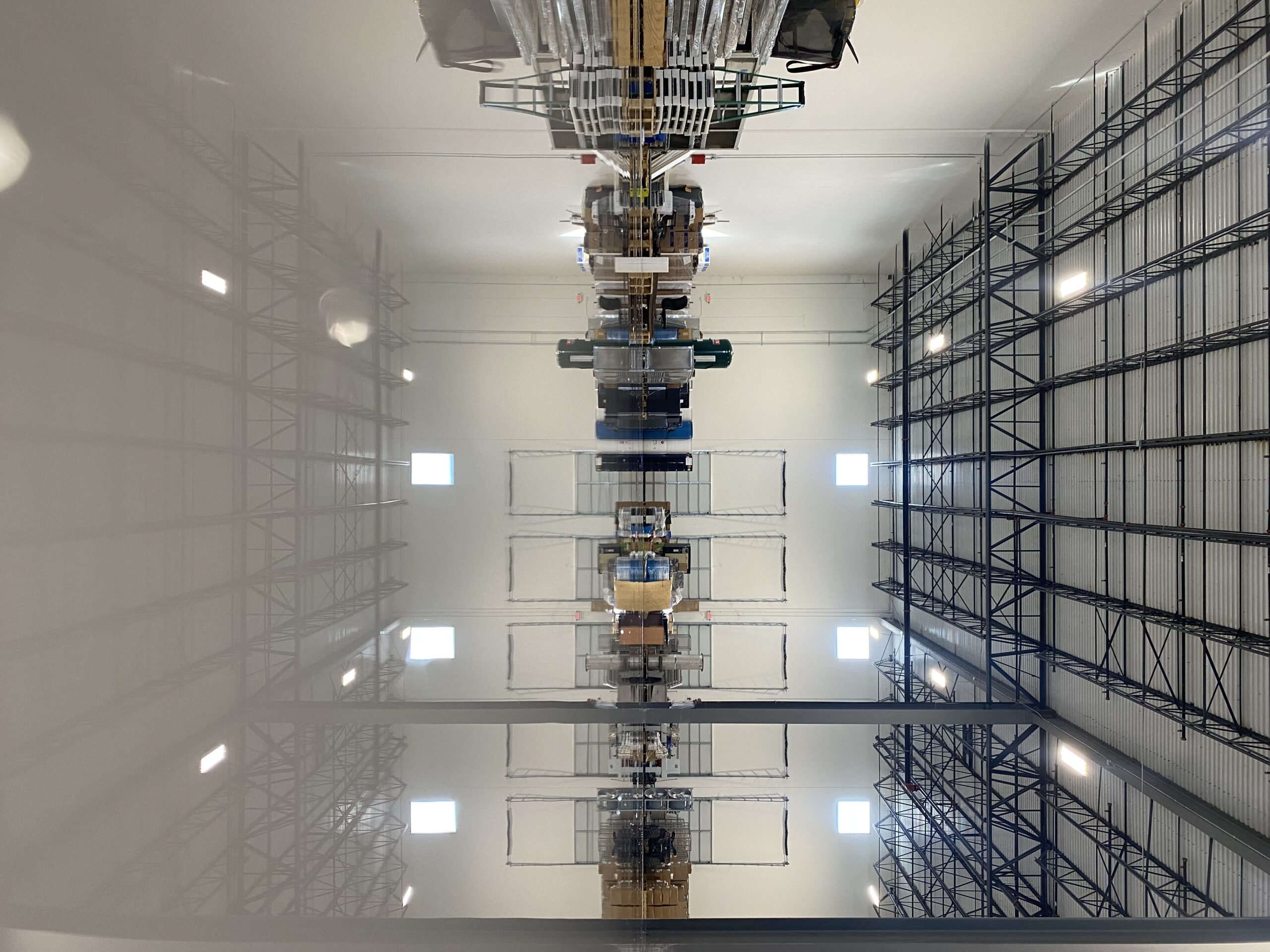

Industrial Epoxy Flooring Solutions

For industrial spaces, epoxy coatings offer durable, versatile flooring solutions. Resilient to heavy machinery, high foot traffic, and chemicals, epoxy provides a seamless, easy-to-clean surface that enhances light reflectivity, potentially reducing the need for extra lighting. Safety is paramount with its slip-resistant properties and resistance to fire, heat, and impact, ensuring a secure environment for workers. Moreover, epoxy's customizable options, from colors to finishes, allow for tailored solutions to match brand aesthetics or create designated safety zones within the facility, accommodating diverse industrial needs with ease.

Common Applications of Epoxy

Automotive Industry

Epoxy is widely used in the automotive industry to coat garage floors, providing a seamless and easy-to-clean surface that can withstand heavy traffic and spills. This application helps to create a clean and functional environment, enhancing both the appearance and durability of garage floors.

Garage and Workshop Spaces

For homeowners who spend time in their garage or workshop, epoxy can transform these areas into clean, bright, and functional spaces. Epoxy coatings are ideal for garage and workshop floors, offering protection against wear and tear, chemicals, and moisture. This not only prolongs the lifespan of the floors but also enhances safety by providing a non-slip surface, ensuring a safe working environment.

Commercial and Industrial Settings

Epoxy coatings are commonly used in commercial and industrial settings to protect concrete floors. These coatings offer durability and resistance to wear and tear, making them suitable for high-traffic areas. By applying epoxy to concrete floors, businesses can prolong the lifespan of their flooring while also enhancing safety with a non-slip surface.

Countertops in Kitchens and Bathrooms

Epoxy is frequently used to coat countertops in kitchens and bathrooms, providing a modern and sleek look to the space. In addition to its aesthetic appeal, epoxy provides a durable and heat-resistant surface that can withstand daily use. This makes it an ideal choice for countertops in areas where durability and functionality are essential.

Whether you're a DIY enthusiast or a business owner looking to upgrade your space, epoxy offers a cost-effective and long-lasting solution for various applications. Its versatility and durability make it suitable for enhancing surfaces in a wide range of environments, from automotive workshops to commercial kitchens.

Our Proposal

Maintenance Tips for Industrial Epoxy

Assessing the specific surface you'll be coating is crucial when selecting the right epoxy.

Benefits of Industrial Epoxy

Enhanced Durability and Performance

Industrial epoxy provides numerous benefits that enhance durability and performance. It creates a sense of security, knowing that your surfaces are protected against wear and tear. The strong bond formed by industrial epoxy makes your floors resilient to heavy traffic and various impacts, fostering a sense of reliability in your working environment.

Professional Appearance

Industrial epoxy offers a smooth and seamless finish, which not only looks professional but also contributes to a cohesive and organized workspace. This aesthetic appeal can boost morale among employees, creating a sense of pride and ownership in the shared space. Imagine walking into your facility and feeling a sense of belonging and care due to the well-maintained floors coated with industrial epoxy.

Easy Maintenance

Moreover, industrial epoxy is easy to clean and maintain, saving you time and effort in upkeep. This convenience allows you to focus on your work without worrying about extensive maintenance routines. By choosing industrial epoxy, you're investing in a long-lasting solution that promotes efficiency and longevity, giving you a sense of stability and confidence in your workspace.

Factors to Consider When Choosing Epoxy

Budget

Lastly, consider your budget when choosing epoxy. Determine how much you're willing to invest in your coating. While quality shouldn't be compromised, there are epoxy options available at different price points to suit your financial plan. By considering these factors, you can confidently choose the epoxy that aligns with your project requirements and preferences.

Application Process

Consider the application process of the epoxy. Do you need a fast-curing epoxy for a quick project turnaround, or do you have the time for a longer curing period for a more precise application? Understanding the application requirements will help you choose the right epoxy for your project timeline and needs.

Aesthetics

Think about the aesthetics you desire for your space. Epoxy coatings come in a variety of colors and finishes, allowing you to customize the look of your surface. Whether you prefer a specific color or a high-gloss finish, make sure to choose an epoxy that meets these preferences and complements your space.

Environmental Conditions

Consider the environment the epoxy will be exposed to. Will it be subject to heavy foot traffic, chemicals, extreme temperatures, or moisture? These factors will help determine the level of durability and resistance your epoxy should have to ensure it performs well in its intended environment.

Surface Type

Assessing the specific surface you'll be coating is crucial when selecting the right epoxy. Whether it's concrete, metal, or wood, each surface may require a different type of epoxy to ensure proper adhesion and longevity.